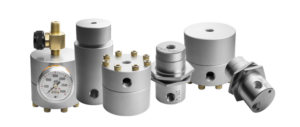

PRESSURE REDUCING REGULATORS

Pressure reducing regulators are installed at the start of a system before pressure sensitive equipment. These regulators precisely reduce / regulate undesirable higher upstream pressure in order to achieve the desired downstream demand. Moreover, pressure reducing regulators will attempt to maintain and control the outlet pressure within certain restraints as other conditions fluctuate. The outlet pressure of your pressure reducing regulator determines the down stream pressure.

Premier offers a wide range of pressure reducing regulators for use in a variety of industries worldwide. Our pressure reducing regulators are offered in varying: materials of construction (with varying degrees of corrosion resistance, weights, strengths, etc.), sizes (ranging from .7” to larger 8” models), flow capacities, and inlet/outlet pressure ranges. With the flexibility of optional port alignments, port sizes/types, relief and shut off valves, loading styles, elastomers, color anodizing, and more, Premier pressure reducing regulators provide maximum versatility and compatibility for your unique product application. If you do not see a standard model that suits your needs, please contact us. We would be happy to help you with a custom design or modification.

‘Pressure Reducing Regulator Quick Look’ provides a comprehensive list of all our pressure reducing regulators listed by their series names.

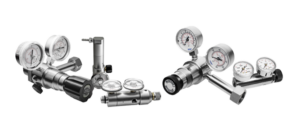

HIGH PRESSURE REGULATORS

Designed to operate with inlet pressures up to 6,000 PSIG. 10K 15K and 20K options are available for select models.

HIGH FLOW REGULATORS

Pressure reducing regulators with a Cv of 1.0 or higher.

HYDRAULIC REGULATORS

Hydraulic regulators are rugged, reliable, and designed to hold a tight seal even as the pressure in the line rises. Premier Industries offers pressure reducing hydraulic regulators in a variety of materials, pressure ranges, porting configurations etc.

DIAPHRAGM SENSED REGULATORS

Diaphragms communicate a change of force to the control element. Diaphragm sensed pressure reducing regulators provide great sensitivity to pressure changes, and are great option for many low pressure applications. Common diaphragm materials include, but are not limited to: Viton ®, Teflon®, Elgiloy®, Buna-N, Neoprene, Hastelloy® and Stainless Steel

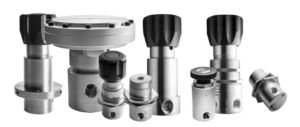

PISTON SENSED REGULATORS

Pistons communicate a change of force to the control element. Pistons sensed regulators are generally better suited for higher outlet pressures than diaphragm sensed regulators.

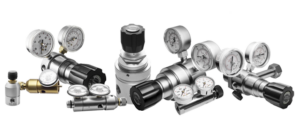

TWO STAGE REGULATORS

Accomplish pressure reduction in two steps, enabling a constant delivery pressure. Two stage regulators are commonly used in situations where the inlet pressure has a tendency to fluctuate and a constant and stable operating pressure is required. Two stage regulators significantly reduce supply pressure effect (also referred to as decaying inlet characteristic).

MINIATURE REGULATORS

These pressure reducing regulators are small and compact in design, easily transportable, light weight, and economically priced.

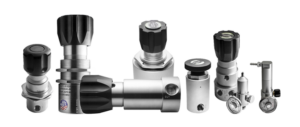

TRANSPORTABLE REGULATORS

Made for use with transportable cylinders, Premier Transportable regulators are reliable, compact solutions to a variety of specialty gas, calibration gas, and other transportable cylinder applications. With a variety of designs, materials, configurations, pressure ranges, flow rates, and an active R&D team, Premier transportable pressure reducing regulators are an ideal choice.

ADJUSTABLE FLOW REGULATORS

Premier’s adjustable flow regulators allow for a variable delivery of flow with the simple twist of a knob. Premier’s adjustable flow regulator has 11 flow settings between 0 and 8.0 SLPM.

AIR LOADED REGULATORS

Pressure reducing regulators that use an air loading mechanism. Also referred to as air actuated regulators.

DOME LOADED REGULATORS

Pressure reducing regulators that use a dome loading mechanism

CYLINDER REGULATORS

Pressure reducing cylinder regulators